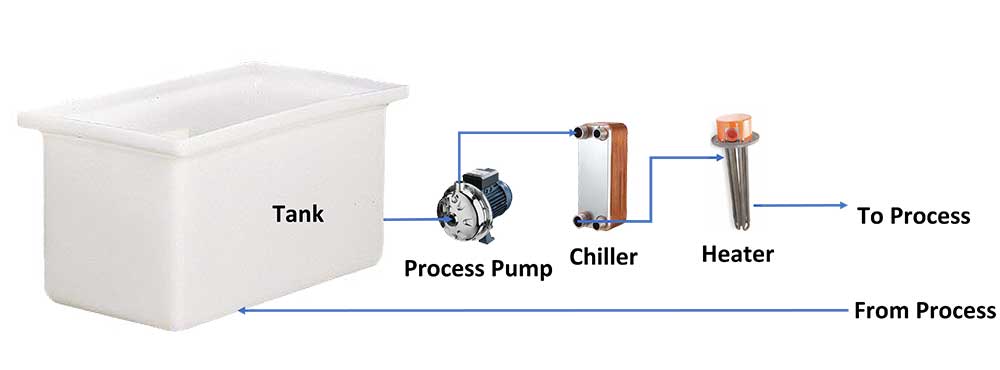

Delta T Systems is introducing a completely new single and dual zone temperature control heater/chiller combo package. These new units allow manufacturers to implement energy efficient control systems that combine highly efficient variable speed compressors and fan motors with a heating loop to control temperature precisely in a broad variety of production processes.

Fully configurable, compact and easy to use, these new Combo Chiller Units include industry proven controls that can log data, predict future issues and provide the necessary control to allow continued operation at a lower, controlled speed before a mandatory maintenance shutdown is required.

Download Technical SpecsCombo Unit Capabilities:

- Chillers can be air or water cooled with a capacity of up to 30 tons

- Heating unit capacity up to 36kw

Key Combo Unit Benefits Include:

- Integrated system saves space and money: both circuits are contained into a common cabinet.

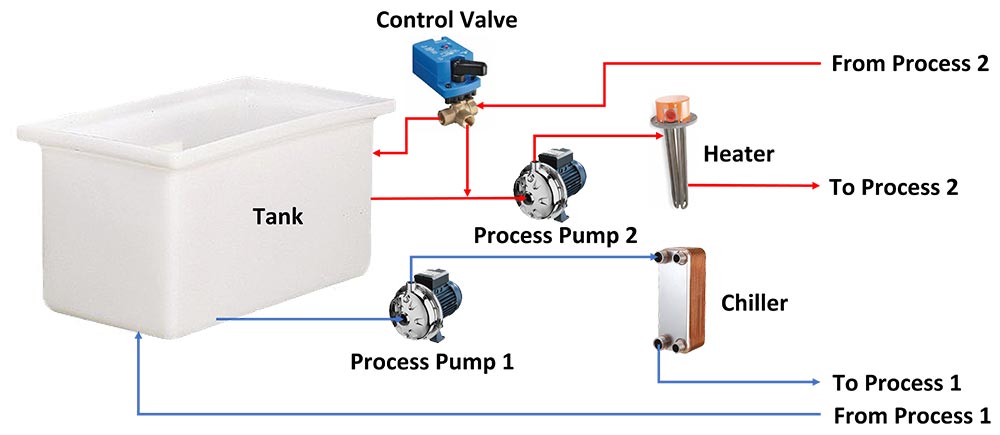

- Standard single controller and program capable of controlling two processes at different temperatures and pumping capacities.

- Precise temperature control within 0.5°F using variable speed compressors, modulating valves, multiple PID control algorithms, and numerous sensors.

- Can be used in any application where Chillers and Temperature Control Units (TCUs) are used in tandem.

- Chiller temperature ranges from -10°F to 100°F (-23°C to 38°C)

- Standard TCU temperatures are 120°F (49°C), optional up to 180°F (82°C) for water

- Variable Speed Chillers can reduce electrical consumption by up to 50% over fixed speed units

- Control program comes with all standard features:

- Adaptive controls

- Data logging

- 4-inch touch screen

- Remote monitoring

- Industry 4.0 ready

Dual Zone Heat/Cool Flow Schematic

Refrigeration Features

- Hermetically sealed variable speed compressor technology

- Energy savings between 30% and 50% of the initial investment

- Soft start

- Less wear and tear compared to compressor cycling

- Inverter drive protects compressor from power spikes

- Tight temperature control within ½ a degree

- Can overspeed compressor to obtain higher capacities

- Stainless steel, copper brazed plate evaporator

- Non-ferrous – will not rust

- Less chance of fouling due to its inherent small channels producing high velocities keeping the channels clear

- Variable speed condenser fan

- Operates at the most efficient point

- Lowers noise since it runs at the minimum speed required

- Electronic expansion valve

- Fine tunes the amount of refrigerant needed to maintain the system at the most efficient operating point

- Allows for a larger operating temperature range without sacrificing temperature control or adding expensive refrigeration controls

- Microchannel aluminum condenser coils

- Less refrigerant required due to smaller refrigerant tubes

- Eliminates galvanic corrosion as seen with copper tube and aluminum fin designs

Water Features

- Evaporator inlet strainer

- Easy access and serviceability for cleaning or removal

- Larger filter area vs. a typical y-strainer equates to less time between cleanings

- Chiller temperature ranges from -10°F to 100°F (-23°C to 38°C)

- TCU temperatures up to 180°F (82°C) for water

- Tight temperature control to within 0.5 °F

Sensor Features

- Refrigerant suction and discharge pressure transducers

- Allows the compressor to adjust its speed to adapt to the best efficient and safe condition to reduce down time

- Actual pressure information is displayed and captured to reduce the time to troubleshoot

- Eliminates fragile copper capillary tubes

- Refrigerant suction and liquid line temperatures sensors for superheat and sub-cool readings

- Compressor discharge temperature sensor for compressor protection

- Chilled water in and out pressure and temperature sensors

- Tank level sensor

Cabinet Features

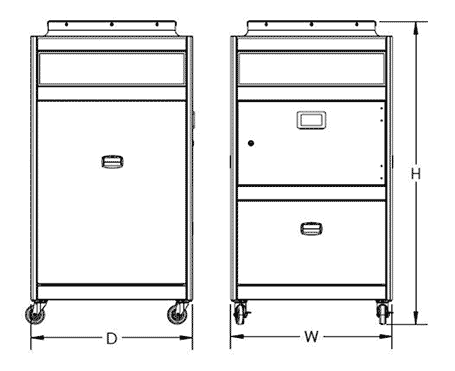

- Fits through a standard 36 inch doorway (needs to be 34-1/2 inches or less to meet this due to door stops)

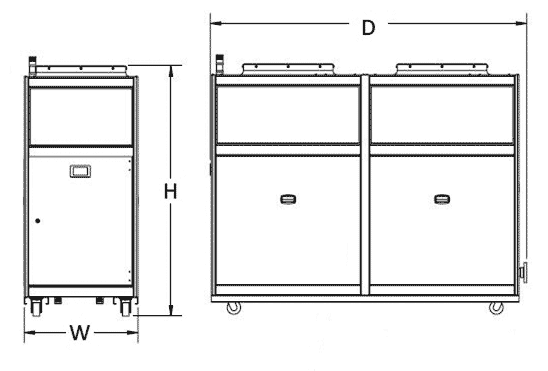

- Small footprint (34×34 on 5 and 7.5 ton, 34×46 on 10 and 15 ton)

- Can fit in standard shipping container – tallest chiller (15 ton) is 85 inches

- Full access on all sides

- Separate air section so chiller can be serviced by removing panel without creating faults

- Round coil allows for locating chiller up against a wall

Electrical Features

- NEMA 12 electrical panel

- Disconnect switch

- 24V controls

- Finger safe electrical components

- Phase monitor

- 4 inch touch screen display

- State of the art controls

- Flexible remote communication options

- Extensive digital data collection

- Adaptive control to reduce downtime

Control Features

- Proprietary Control Platform from the leader in the HVAC and refrigeration industry

- Integrated Ethernet interfaces offer a wide range of open protocols (Web server, Modbus/TCP, BACNet, FTP, DHCP, DNS, NTP) (optional)

- Cloud services (optional)

- 4 Inch Touch Screen Display

- Adaptive Control

- Uses the systems pressures, temperatures, and compressor drive information to operate the chiller at the most efficient operating point while maintaining the predefined compressor operating envelope limits

- Changes the speed of the compressor should any of the parameters approach a fault condition in order to reduce customer downtime.

- Data Logging

- Logs temperature and pressure data continually for historical reference

- Captures data at the time of an alarm event

- Remote Monitoring (optional)

Bonus Features

- Dewpoint sensing and setpoint tracking

- 50 Hz applications without a cooling capacity de-rate

- Modbus RTU or BACnet MS/TP RS485 communication

- Remote start/stop

- Cooling enabled output

- Automatic water bypass

- Flow indication

- Dirty strainer indication

- Tank level indication

- Low and high level indication

Options

- Remote display

- Outdoor construction

- Overhead piping kit

- Mounting feet in lieu of casters

- No pump, no tank

- Pump, no tank

- Ship loose pump, no tank

- Auto water make-up

- 50 micron side stream filter (factory installed)

- 50 micron full flow filter (factory installed)

- High Operating Temp Option for 180F

- Alarm horn

- Alarm strobe

- Remote alarm contacts

- Remote access to control

- UL 508a

- SNMP, Modbus TCP/IP, BACnet Ethernet Communication

| Model5 | Maximum Capacity1 (BTUH) | Minimum Load (BTUH) | Condenser Air Flow (CFM) | Reservoir (Gallons) | Minimum Circuit Ampacity2 | Heating Capacity (kW) | Dimensions (in) Height3, Width, Depth | Shipping Weight (with crate) (lbs) |

||

|---|---|---|---|---|---|---|---|---|---|---|

| VSPAH2-005-XX | 65,653 | 6,001 | 3,317 | 25 | 33.1 | 9, 12, 18, 24, 36 | 64 | 34 | 46 | 755 |

| VSPAH2-008-XX | 88,969 | 9,005 | 4,541 | 25 | 34.6 | 9, 12, 18, 24, 36 | 75 | 34 | 46 | 829 |

| VSPAH2-010-XX | 138,205 | 12,004 | 6,569 | 40 | 45.3 | 9, 12, 18, 24, 36 | 75 | 34 | 46 | 943 |

| VSPAH2-015-XX | 182,712 | 18,003 | 9,726 | 40 | 57.1 | 9, 12, 18, 24, 36 | 85 | 34 | 46 | 953 |

| VSPAH2-020-XX | 276,674 | 24,008 | 13,138 | 70 | 65.1 | 9, 12, 18, 24, 36 | 75 | 34 | 95 | 1,740 |

| VSPAH2-025-XX | 326,125 | 30,020 | 19,452 | 70 | 78.4 | 9, 12, 18, 24, 36 | 75 | 34 | 95 | 1,855 |

| VSPAH2-030-XX | 365,425 | 36,006 | 19,452 | 70 | 87.2 | 9, 12, 18, 24, 36 | 86 | 34 | 95 | 1,935 |

| (1) Capacity based on 50°F LWT, 85°F condenser inlet water, maximum speed (2) MCA based on standard pump option and smallest heater. Will change with different pumps and heaters. (3) Add approximately 6” for optional alarm horn and strobe. (4) Shipping weight based on standard pump options and smallest heating capacity. (5) "XX" placeholder for heating capacity, i.e. "12" for 12kw. |

||||||||||

VSPAH2-005-XX to VSPH1-015-XX

VSPAH2-005-XX to VSPH1-015-XX VSPAH2-020-XX to VSPAH1-030-XX

VSPAH2-020-XX to VSPAH1-030-XXSingle and dual zone units fit into the same cabinet

Download Technical Specs