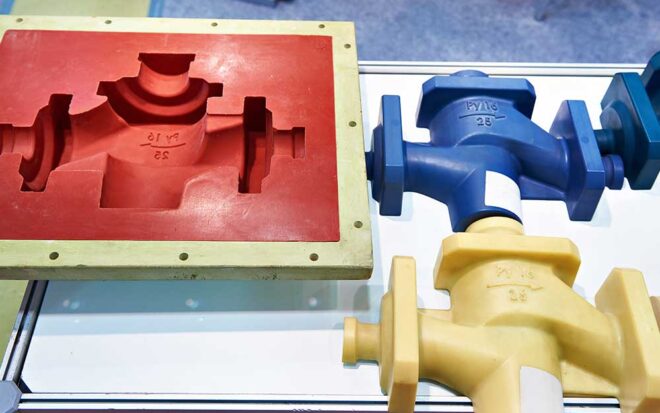

Delta T Systems manufactures Water and Oil Temperature Control Equipment, Portable Air and Water Cooled Chillers and Industrial Central Chillers. Our full line of system solutions is available in many sizes to fit all process needs, with temperature control ranges from -10°F (-23°C) up to 550°F (288°C). Incorporating sound fundamental engineering principles ensures that users receive accurate and reliable temperature control and years of unmatched performance. Delta T Systems’ American made high quality temperature control units, are competitively priced and will perform to spec for a broad spectrum of industries including: plastics, rubber, textile, chemical, food processing, pulp and paper, petrochemical, pharmaceutical, medical, semi-conductor, adhesives and resins, pet food processing, textiles, cosmetics and thermoforming. The main applications are temperature control for molds, dies, tanks, jacketed vessels, mixers, extrusion and heat transfer rolls. One of Delta T Systems’ specialties is custom designs for special processes and applications.

Delta T Systems is a premier OEM equipment replacement parts provider. We stock a wide selection of Controllers, Pumps, Heaters and Electrical Components – all manufactured by industry recognized suppliers like Carel, Viking, Omron, Watlow, ASCO, Paratherm and more. The replacement parts we stock are for general use in industrial equipment, as well as for specific Delta T Systems Temperature Control Units and Chillers.